-

Electromechanical Universal Testing Machine

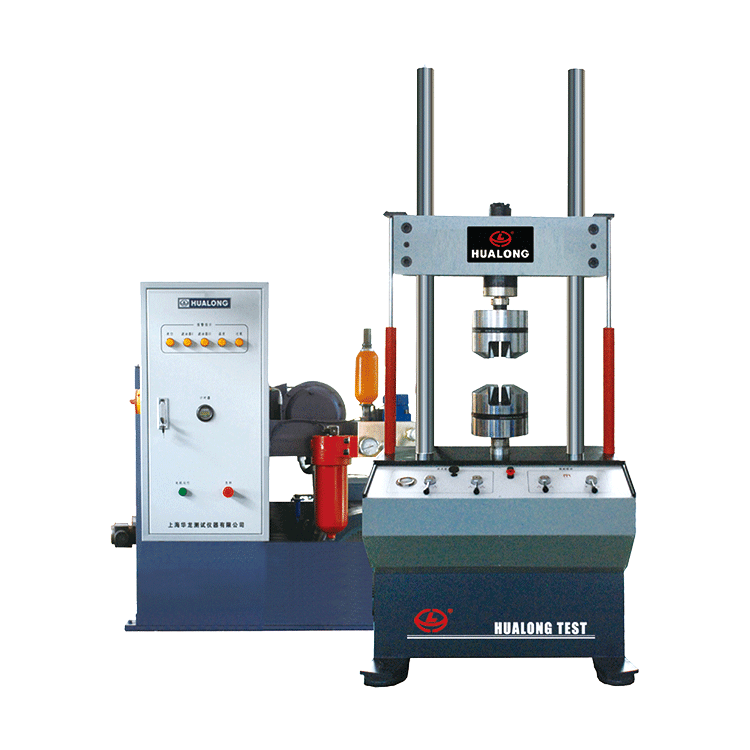

- Hydraulic Universal Testing Machine

- Automated Testing Systems

-

Horizontal Tensile Testing Machine

-

Elastomeric Bearing Testing Machine

-

Compression Testing Machine

-

High Temperature Creep Testing Machine

- Impact Testing Systems

-

Dynamic Testing Systems

-

Torsion Testing Machine

-

Bending Testing Machine

- Special Testing Machine

- Non-Metal Testing Machine

- Hardness Tester

- Metallographic Preparation Equipment

-

Microscope

NDT Pendulum impact testing machine

The equipment consists of an electronically controlled operating system, a low temperature control system, a feeding device and a centering device, a host system, an anti-secondary strike device, and a safety protection system.

1.2.1.1. Electronically controlled operating system:

Adopting the man-machine interface touch screen operation mode, first select the corresponding sample type on the touch screen according to the sample type, and set various test parameters, such as: hammer weight, set drop height, energy, sample number and the like. And enter it on the touch screen, or directly input the required impact energy. Press the preparatory button, at this time, the test machine will automatically raise the hammer to the set height. The operator will take the sample that has reached the constant temperature requirement from the incubator, put it into the sample feeding device, and push the sample into the anvil table. Upper, end positioning, automatic centering, closing the protective door, starting the drop hammer button, the hammer body automatically falls, complete the single piece impact test. Test data display window. After the impact is completed, press the preparatory button again, and the lock hammer mechanism will automatically grab the hammer and lift the hammer. At the same time, the sample delivery device can be pulled back to the initial device and awaiting the second impact test. Manual manual operation can be performed when the automatic system fails. When the equipment is inspected, the maintenance personnel can perform step-by-step operations on each unit's actions.

1.2.1.2. Low temperature control system (the low temperature system is not mentioned in this tender)

Temperature control range: room temperature ~ -80 ° C, temperature control accuracy ≤ 0.5 ° C, temperature gradient ≤ 2 ° C. The longest heating time: room temperature ~ -100 ° C < 2 hours. The device can simultaneously place 6-8 P-2 samples. The sample has a stirring function to ensure temperature uniformity in the presence of a cooling medium. The temperature change was directly observed on the temperature control digital display. The refrigeration system uses a two-stage duplex cooling and a dual pump start. It has a constant temperature time prompt function, and when it reaches the set constant temperature time, there will be a peaking sound.

1.2.1.3. Feeding device and centering device

Manually take out the standard sample from the cryostat and put it into the feeding device. The device adopts the crank-and-rod mechanism, and pushes the handrail to send the sample to the impacting anvil. It is automatically centered and does not need to take the feeding device. After the impact is completed, the feeding device and the waste material are pulled back to the initial position to wait for the second sample to be placed. Suitable for P-2, P-3, P-4 samples. The centering device is mounted on the anvil and the end of the sample is positioned for error adjustment.

1.2.1.4. Host System

The main machine is composed of a transmission mechanism, a hammer body component, a lifting mechanism, a hammer tracking device, a guide rail, a frame of the base, and the like.

a. transmission mechanism

It is equipped with a Japanese Shima brand geared motor and has a power-off brake. If the motor locks down and the entire transmission system stops during a sudden power failure during the rise or fall of the hammer, it can prevent the hammer from slipping and accident.

b. Hammer parts

The hammer body adopts the overall Structure of the cast steel piece, the rigidity is good, the punch and the hammer body are combined, and the high-quality alloy steel material is used, the hardness reaches HRC58-62, and the curvature radius R25 of the punch. The upper part of the hammer body is provided with a hook self-locking structure.

c. Lifting mechanism

Adopting the sprocket chain transmission mode, the lifting speed is 1.1m/min, slowly lowering the lock hammer and lifting the hammer. The limit control switch is installed and automatically stopped.

d. Lifting hammer tracking device

Through the lowering of the hammer tracking device, the hammer body is automatically locked after contact with the hammer body, and the joint body is slowly raised under the action of the lifting mechanism. After reaching the set height, the limit component quickly transmits a signal to stop the transmission system from rotating and the hammer stops at the set height. When the impact command is received, the lock hammer device quickly releases the hammer body and moves freely along the guide rail. Complete the impact test. The lock hammer and the release mechanism have a self-locking device, and the hook-and-drop phenomenon does not occur in the event of a sudden power failure. Safe and reliable.

e. Guide rail

It is processed into a smooth surface with two φ54×12 seamless steel tubes and then chrome-plated.

f. frame frame

The base is made of ZG45 cast steel material. The column adopts four φ83×12 seamless steel tubes, and the top plate is made of thick steel plate to ensure the rigidity and strength requirements.

1.2.1.5. Anti-secondary strike device

Two working table surfaces are respectively mounted on the base of the hammer body landing position, and a push-type electromagnet lever mechanism is mounted on the table surface. When the hammer blade hits the sample, the photoelectric signal is instantaneously transmitted to the electromagnet to push the lever. Pushing the anti-secondary strike block into the hammer gap that rebounds upwards, propping up the drop hammer, and not causing the hammer blade to fall on the sample twice, effectively preventing the "secondary" strike.

1.2.1.6. Safety protection device

It adopts 1m high steel mesh protection device and is equipped with electric control device for closing the door. The protective door is not closed, and the operating system is always closed and cannot be started.

1.2.1.7. Data Acquisition System

The motor output shaft is coaxially mounted with a rotary encoder imported from South Korea. Its high precision and resolution of 0.1o can accurately control the accuracy of the lifting position.

1.2.1.1. Electronically controlled operating system:

Adopting the man-machine interface touch screen operation mode, first select the corresponding sample type on the touch screen according to the sample type, and set various test parameters, such as: hammer weight, set drop height, energy, sample number and the like. And enter it on the touch screen, or directly input the required impact energy. Press the preparatory button, at this time, the test machine will automatically raise the hammer to the set height. The operator will take the sample that has reached the constant temperature requirement from the incubator, put it into the sample feeding device, and push the sample into the anvil table. Upper, end positioning, automatic centering, closing the protective door, starting the drop hammer button, the hammer body automatically falls, complete the single piece impact test. Test data display window. After the impact is completed, press the preparatory button again, and the lock hammer mechanism will automatically grab the hammer and lift the hammer. At the same time, the sample delivery device can be pulled back to the initial device and awaiting the second impact test. Manual manual operation can be performed when the automatic system fails. When the equipment is inspected, the maintenance personnel can perform step-by-step operations on each unit's actions.

1.2.1.2. Low temperature control system (the low temperature system is not mentioned in this tender)

Temperature control range: room temperature ~ -80 ° C, temperature control accuracy ≤ 0.5 ° C, temperature gradient ≤ 2 ° C. The longest heating time: room temperature ~ -100 ° C < 2 hours. The device can simultaneously place 6-8 P-2 samples. The sample has a stirring function to ensure temperature uniformity in the presence of a cooling medium. The temperature change was directly observed on the temperature control digital display. The refrigeration system uses a two-stage duplex cooling and a dual pump start. It has a constant temperature time prompt function, and when it reaches the set constant temperature time, there will be a peaking sound.

1.2.1.3. Feeding device and centering device

Manually take out the standard sample from the cryostat and put it into the feeding device. The device adopts the crank-and-rod mechanism, and pushes the handrail to send the sample to the impacting anvil. It is automatically centered and does not need to take the feeding device. After the impact is completed, the feeding device and the waste material are pulled back to the initial position to wait for the second sample to be placed. Suitable for P-2, P-3, P-4 samples. The centering device is mounted on the anvil and the end of the sample is positioned for error adjustment.

1.2.1.4. Host System

The main machine is composed of a transmission mechanism, a hammer body component, a lifting mechanism, a hammer tracking device, a guide rail, a frame of the base, and the like.

a. transmission mechanism

It is equipped with a Japanese Shima brand geared motor and has a power-off brake. If the motor locks down and the entire transmission system stops during a sudden power failure during the rise or fall of the hammer, it can prevent the hammer from slipping and accident.

b. Hammer parts

The hammer body adopts the overall Structure of the cast steel piece, the rigidity is good, the punch and the hammer body are combined, and the high-quality alloy steel material is used, the hardness reaches HRC58-62, and the curvature radius R25 of the punch. The upper part of the hammer body is provided with a hook self-locking structure.

c. Lifting mechanism

Adopting the sprocket chain transmission mode, the lifting speed is 1.1m/min, slowly lowering the lock hammer and lifting the hammer. The limit control switch is installed and automatically stopped.

d. Lifting hammer tracking device

Through the lowering of the hammer tracking device, the hammer body is automatically locked after contact with the hammer body, and the joint body is slowly raised under the action of the lifting mechanism. After reaching the set height, the limit component quickly transmits a signal to stop the transmission system from rotating and the hammer stops at the set height. When the impact command is received, the lock hammer device quickly releases the hammer body and moves freely along the guide rail. Complete the impact test. The lock hammer and the release mechanism have a self-locking device, and the hook-and-drop phenomenon does not occur in the event of a sudden power failure. Safe and reliable.

e. Guide rail

It is processed into a smooth surface with two φ54×12 seamless steel tubes and then chrome-plated.

f. frame frame

The base is made of ZG45 cast steel material. The column adopts four φ83×12 seamless steel tubes, and the top plate is made of thick steel plate to ensure the rigidity and strength requirements.

1.2.1.5. Anti-secondary strike device

Two working table surfaces are respectively mounted on the base of the hammer body landing position, and a push-type electromagnet lever mechanism is mounted on the table surface. When the hammer blade hits the sample, the photoelectric signal is instantaneously transmitted to the electromagnet to push the lever. Pushing the anti-secondary strike block into the hammer gap that rebounds upwards, propping up the drop hammer, and not causing the hammer blade to fall on the sample twice, effectively preventing the "secondary" strike.

1.2.1.6. Safety protection device

It adopts 1m high steel mesh protection device and is equipped with electric control device for closing the door. The protective door is not closed, and the operating system is always closed and cannot be started.

1.2.1.7. Data Acquisition System

The motor output shaft is coaxially mounted with a rotary encoder imported from South Korea. Its high precision and resolution of 0.1o can accurately control the accuracy of the lifting position.

Need help or have a question?

For more information on how Hualong can help your company profit through testing, please Click the button.FRIEND LINK:

CONTACT US

No. 389 Chuanhong Road, Pudong New Area, Shanghai 201202, China

Tel: +86 17821945087

Online Service: 7*24h

© 2018 HUALONG All rights reserved. SiteMap