-

Electromechanical Universal Testing Machine

- Hydraulic Universal Testing Machine

- Automated Testing Systems

-

Horizontal Tensile Testing Machine

-

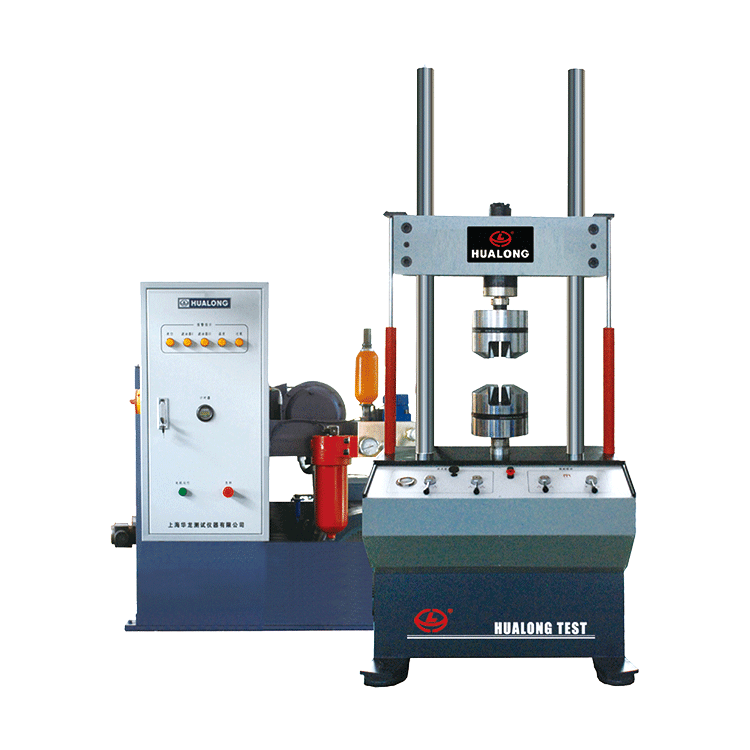

Elastomeric Bearing Testing Machine

-

Compression Testing Machine

-

High Temperature Creep Testing Machine

- Impact Testing Systems

-

Dynamic Testing Systems

-

Torsion Testing Machine

-

Bending Testing Machine

- Special Testing Machine

- Non-Metal Testing Machine

- Hardness Tester

- Metallographic Preparation Equipment

-

Microscope

Drop Weight Tear Tester (Automatic Specimen Feeding System)

•Very robust construction stands up to the rigors of high energy testing to provide high reliability with a minimum of downtime.

•The buffer is equipped to absorb the residual energy after breaking the specimen to protect the weight and anvil from destroying. Also install the safe outfit, such as safety net, safe pin for maintenance and hanger locking.

•Easily interchangeable contact parts simplify maintenance and reduce cost of ownership.

•State-of-the-art testing accommodates impact energies up to 100,000J and specimens up to 50mm thick.

•Automated specimen loading provides compliance with cycle times required by test methods, while maintaining operator safety.

•Very rigid base and anvils ensures very low flexure under high test loads.

•Guided mass system to ensure that the impact geometry is correct throughout the entire test.

•Equipped with the specimen-carrying outfit, anti-falling of outfit for the specimen, centering outfit to guarantee quick, accurate and reliable tests.

•High quality, easy to use control software ensures consistency and enhances throughput.

•Ergonomically designed, no requirement for the operator to work at elevated heights or handle excessive physical loads.

•Optional liquid low temperature chamber.

•Optional automatic specimen feeding system.

•Optional Impact data acquisition system.

•Responsive life-time technical support.

Need help or have a question?

For more information on how Hualong can help your company profit through testing, please Click the button.FRIEND LINK:

No. 389 Chuanhong Road, Pudong New Area, Shanghai 201202, China

Tel: +86 17821945087

Online Service: 7*24h

© 2018 HUALONG All rights reserved. SiteMap