-

Electromechanical Universal Testing Machine

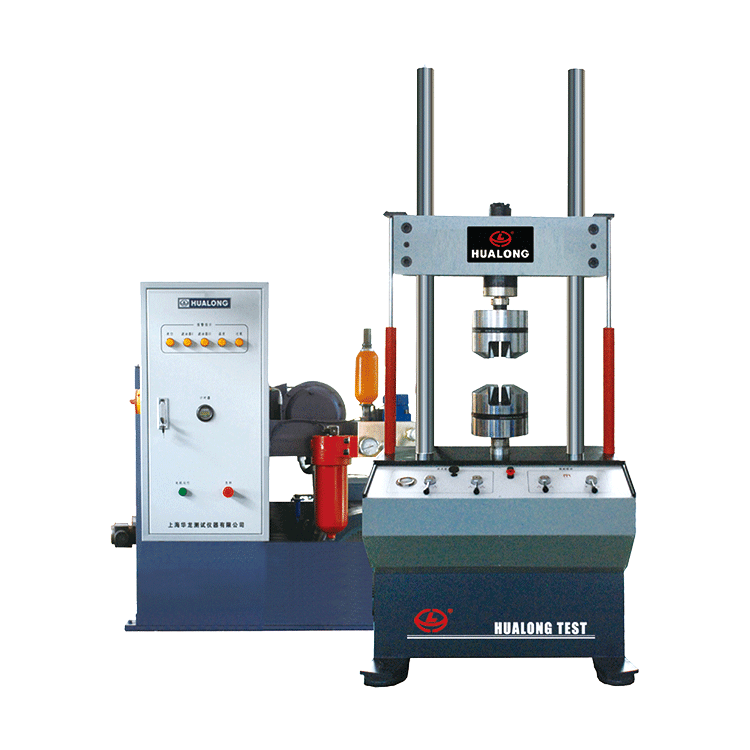

- Hydraulic Universal Testing Machine

- Automated Testing Systems

-

Horizontal Tensile Testing Machine

-

Elastomeric Bearing Testing Machine

-

Compression Testing Machine

-

High Temperature Creep Testing Machine

- Impact Testing Systems

-

Dynamic Testing Systems

-

Torsion Testing Machine

-

Bending Testing Machine

- Special Testing Machine

- Non-Metal Testing Machine

- Hardness Tester

- Metallographic Preparation Equipment

-

Microscope

Electro-hydraulic servo static and dynamic universal testing machine

The electro-hydraulic servo static and dynamic Universal Testing Machine is mainly used for testing the dynamic and static mechanical properties of various materials in various fields such as mechanical metallurgy, aerospace, universities, research institutes, etc. It can also be professionally designed according to user requirements to realize parts and components. Dynamic and static performance tests. The main tests are tensile, compression, bending, low cycle and high cycle fatigue, crack propagation, and fracture mechanics tests.

The operation of the machine is flexible and convenient, the beam is lifted and clamped, and the sample clamping is completed by the electric button automatic hydraulic clamping system. The control system adopts the industrial control chassis with good anti-interference performance as the main chassis, and each function board adopts ISA bus template design, and the maintenance is good. The computer interface adopts virtual panel technology, which is convenient to operate, and can load test waveforms such as sine wave, square wave, triangle wave, oblique wave, combined wave, combined oblique wave and external input acquisition wave in real time.

Static test

Tensile, compression, bending test.

Dynamic fatigue test.

Sine wave, triangle wave, square wave, ramp wave, sawtooth wave test

You can set the amplitude, average, and frequency of the test waveform.

Multi-section combination ramp can be set

Multiple sets of various waveform combinations can be set

Fatigue crack growth test

High and low cycle fatigue test

Display test data, real-time curve

Perform various simulation loading tests by external input waves

Data processing and analysis

Static test data processing.

Dynamic test data analysis

Test result printing

Test curve drawing

Performance

Control method: displacement, load, deformation.

Displacement Amplifier: The measurement is divided into 250%, 50%, 20%, and 10%. The accuracy of both directions is ± 0.5%·FS of full scale (20% of full stroke).

Load Amplifier: The measurement is divided into 250%, 50%, 20%, and 10%. The accuracy of both directions is ±1% of the indicated value (20% of full stroke).

Deformation Amplifier: The measurement is divided into four parts of 250%, 50%, 20%, and 10%. The accuracy of both directions of tension and pull is ± 0.5% of the indicated value (from 20% of full stroke).

Computer control: The load computer automatically zeros and shifts gears. Displace the computer to shift gears. The deformation computer is zeroed and shifted. Displacement, load P, I, D computer adjustment. Function generator waveform control. The three control modes of displacement, load and deformation are smoothly switched.

Function generator: The waveform has sine wave, triangle wave, square wave, ramp wave, positive sawtooth wave, negative sawtooth wave, combined wave, combined oblique wave.

Frequency range 0.001HZ –250HZ

Safety protection: overload protection, limit protection, break protection, fatigue protection, emergency stop

Other: Remote oil source control.

The operation of the machine is flexible and convenient, the beam is lifted and clamped, and the sample clamping is completed by the electric button automatic hydraulic clamping system. The control system adopts the industrial control chassis with good anti-interference performance as the main chassis, and each function board adopts ISA bus template design, and the maintenance is good. The computer interface adopts virtual panel technology, which is convenient to operate, and can load test waveforms such as sine wave, square wave, triangle wave, oblique wave, combined wave, combined oblique wave and external input acquisition wave in real time.

Static test

Tensile, compression, bending test.

Dynamic fatigue test.

Sine wave, triangle wave, square wave, ramp wave, sawtooth wave test

You can set the amplitude, average, and frequency of the test waveform.

Multi-section combination ramp can be set

Multiple sets of various waveform combinations can be set

Fatigue crack growth test

High and low cycle fatigue test

Display test data, real-time curve

Perform various simulation loading tests by external input waves

Data processing and analysis

Static test data processing.

Dynamic test data analysis

Test result printing

Test curve drawing

Performance

Control method: displacement, load, deformation.

Displacement Amplifier: The measurement is divided into 250%, 50%, 20%, and 10%. The accuracy of both directions is ± 0.5%·FS of full scale (20% of full stroke).

Load Amplifier: The measurement is divided into 250%, 50%, 20%, and 10%. The accuracy of both directions is ±1% of the indicated value (20% of full stroke).

Deformation Amplifier: The measurement is divided into four parts of 250%, 50%, 20%, and 10%. The accuracy of both directions of tension and pull is ± 0.5% of the indicated value (from 20% of full stroke).

Computer control: The load computer automatically zeros and shifts gears. Displace the computer to shift gears. The deformation computer is zeroed and shifted. Displacement, load P, I, D computer adjustment. Function generator waveform control. The three control modes of displacement, load and deformation are smoothly switched.

Function generator: The waveform has sine wave, triangle wave, square wave, ramp wave, positive sawtooth wave, negative sawtooth wave, combined wave, combined oblique wave.

Frequency range 0.001HZ –250HZ

Safety protection: overload protection, limit protection, break protection, fatigue protection, emergency stop

Other: Remote oil source control.

Need help or have a question?

For more information on how Hualong can help your company profit through testing, please Click the button.FRIEND LINK:

CONTACT US

No. 389 Chuanhong Road, Pudong New Area, Shanghai 201202, China

Tel: +86 17821945087

Online Service: 7*24h

© 2018 HUALONG All rights reserved. SiteMap