-

Electromechanical Universal Testing Machine

- Hydraulic Universal Testing Machine

- Automated Testing Systems

-

Horizontal Tensile Testing Machine

-

Elastomeric Bearing Testing Machine

-

Compression Testing Machine

-

High Temperature Creep Testing Machine

- Impact Testing Systems

-

Dynamic Testing Systems

-

Torsion Testing Machine

-

Bending Testing Machine

- Special Testing Machine

- Non-Metal Testing Machine

- Hardness Tester

- Metallographic Preparation Equipment

-

Microscope

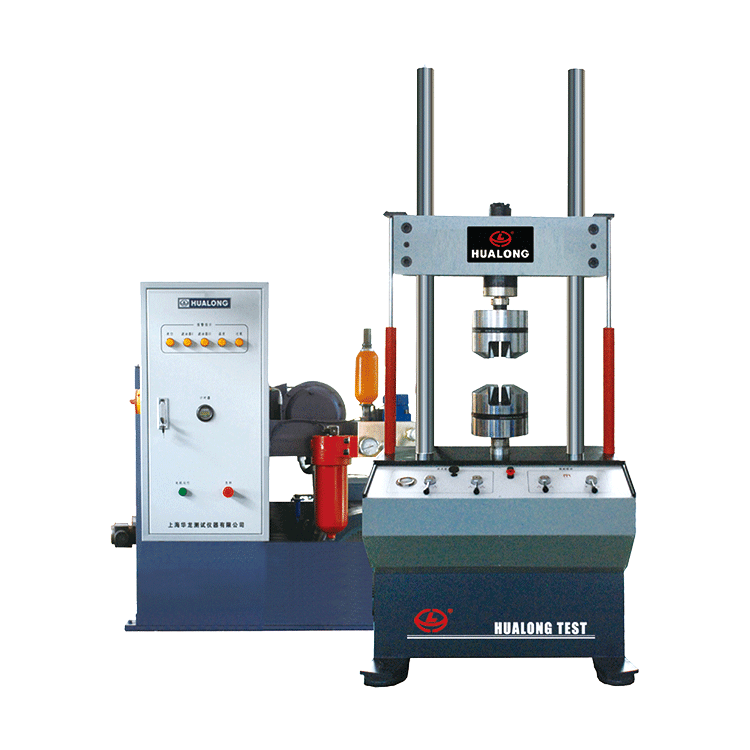

Electro-hydraulic servo pressure testing machine

The electro-hydraulic servo pressure tester is suitable for testing the mechanical properties of materials such as core samples, refractory bricks, concrete and other Products.

It meets the requirements of relevant standards such as GB/T2611-92, JJG139-1999 and GB/T50081-2002.

It is mainly used for the testing and analysis of the mechanical properties of raw materials, incoming materials and finished products in the fields of colleges and universities, factories and mines, quality supervision departments, and metrological verification.

Host

The host adopts an overall frame Structure. It has the characteristics of beautiful appearance, high strength and small size. The main working cylinder is the key component. In order to ensure its sensitivity, low friction and pressure stability, the design adopts international advanced composite sealing technology, and selects high-quality materials and special techniques for precise production. It is equipped with safety limit and piston position indication. Ruler and so on.

Control and measurement system

Auto CTS-550 screen display full digital multi-channel closed-loop measurement and control system adopts industrial control bus slot structure, each functional module is self-contained, owns 40M main frequency CPU, and multiple CPUs in one system (in one system) At least 4 in parallel work in parallel, realizing multi-task parallel operation in the true sense. In the past, a single CPU system relied on external event interrupt mode to process tasks cyclically, and the other was timer interrupt mode to handle multi-tasks. One is also the multi-tasking working mode adopted by Windows. These two methods cannot process concurrent events in parallel, and cannot respond to the real-time response of the industrial control process. The Auto CTS-550 screen-display all-digital multi-channel closed-loop measurement and control system is specially designed for this purpose. It uses multiple CPUs to process different engineering quantities at the same time, which has faster data processing speed than traditional single CPU systems. The efficiency is improved by more than 600%, and the PID control adjustment response is rapid and has strong real-time performance.

Due to the plug-separation technology using sensor correction data, an unlimited number of sensors can be expanded on one A/D board. On the other hand, at least 5 systems can be connected in one system by means of the system's PnP (Plug and Play) technology. A/D board greatly expands the applicability of the system to various applications.

Control and measurement system features:

Multiple high-speed CPUs work in parallel, realizing multi-tasking and parallel work in the true sense.

Modular unit: Flexible interchange of various Accessories, industrial control bus type electrical hardware, easy to function expansion and maintenance.

With the modular structure of the industrial bus slot, the function expansion is easier and the maintenance service is more convenient.

The high-precision ±500000-code acquisition card has a resolution of up to 1/±50000 yards, which makes the measurement range of the sensor to the extreme.

The PnP (Plug and Play) technology of the computer and Windows system is used to automatically recognize the inserted card.

The sensor separation data plug separation technology allows unlimited expansion of the sensor on a single device.

Backup support for sensor correction data provides highly reliable data measurement accuracy.

The linear compensation function of the sensor up to 20 segments can increase the accuracy level of the machine if necessary.

The scene-style operation menu display makes it easy to switch between different menus.

Up to 576k communication baud rate enables fast data exchange with large computers.

The test stand position memory function can realize the test bench position protection of the software setting.

The digital counting frequency of up to 10M ensures that the displacement and the large extended digital count are eliminated.

The anti-shake frequency doubling technique of the encoder signal increases the displacement and the resolution of the large extension by several times.

The closed-loop control function of any channel realizes not only closed-loop control of load and displacement.

The visual PID adjustment immediately shows the result of PID parameter adjustment, so that the PID is no longer "not visible."

Fast and independent overload protection for rapid protection of equipment in the event of an overload.

The associated three-level test bench is limited in position to ensure foolproof protection.

The computer remote shutdown function allows the host to automatically turn off the power by tapping the mouse on the computer screen.

It meets the requirements of relevant standards such as GB/T2611-92, JJG139-1999 and GB/T50081-2002.

It is mainly used for the testing and analysis of the mechanical properties of raw materials, incoming materials and finished products in the fields of colleges and universities, factories and mines, quality supervision departments, and metrological verification.

Host

The host adopts an overall frame Structure. It has the characteristics of beautiful appearance, high strength and small size. The main working cylinder is the key component. In order to ensure its sensitivity, low friction and pressure stability, the design adopts international advanced composite sealing technology, and selects high-quality materials and special techniques for precise production. It is equipped with safety limit and piston position indication. Ruler and so on.

Control and measurement system

Auto CTS-550 screen display full digital multi-channel closed-loop measurement and control system adopts industrial control bus slot structure, each functional module is self-contained, owns 40M main frequency CPU, and multiple CPUs in one system (in one system) At least 4 in parallel work in parallel, realizing multi-task parallel operation in the true sense. In the past, a single CPU system relied on external event interrupt mode to process tasks cyclically, and the other was timer interrupt mode to handle multi-tasks. One is also the multi-tasking working mode adopted by Windows. These two methods cannot process concurrent events in parallel, and cannot respond to the real-time response of the industrial control process. The Auto CTS-550 screen-display all-digital multi-channel closed-loop measurement and control system is specially designed for this purpose. It uses multiple CPUs to process different engineering quantities at the same time, which has faster data processing speed than traditional single CPU systems. The efficiency is improved by more than 600%, and the PID control adjustment response is rapid and has strong real-time performance.

Due to the plug-separation technology using sensor correction data, an unlimited number of sensors can be expanded on one A/D board. On the other hand, at least 5 systems can be connected in one system by means of the system's PnP (Plug and Play) technology. A/D board greatly expands the applicability of the system to various applications.

Control and measurement system features:

Multiple high-speed CPUs work in parallel, realizing multi-tasking and parallel work in the true sense.

Modular unit: Flexible interchange of various Accessories, industrial control bus type electrical hardware, easy to function expansion and maintenance.

With the modular structure of the industrial bus slot, the function expansion is easier and the maintenance service is more convenient.

The high-precision ±500000-code acquisition card has a resolution of up to 1/±50000 yards, which makes the measurement range of the sensor to the extreme.

The PnP (Plug and Play) technology of the computer and Windows system is used to automatically recognize the inserted card.

The sensor separation data plug separation technology allows unlimited expansion of the sensor on a single device.

Backup support for sensor correction data provides highly reliable data measurement accuracy.

The linear compensation function of the sensor up to 20 segments can increase the accuracy level of the machine if necessary.

The scene-style operation menu display makes it easy to switch between different menus.

Up to 576k communication baud rate enables fast data exchange with large computers.

The test stand position memory function can realize the test bench position protection of the software setting.

The digital counting frequency of up to 10M ensures that the displacement and the large extended digital count are eliminated.

The anti-shake frequency doubling technique of the encoder signal increases the displacement and the resolution of the large extension by several times.

The closed-loop control function of any channel realizes not only closed-loop control of load and displacement.

The visual PID adjustment immediately shows the result of PID parameter adjustment, so that the PID is no longer "not visible."

Fast and independent overload protection for rapid protection of equipment in the event of an overload.

The associated three-level test bench is limited in position to ensure foolproof protection.

The computer remote shutdown function allows the host to automatically turn off the power by tapping the mouse on the computer screen.

Need help or have a question?

For more information on how Hualong can help your company profit through testing, please Click the button.FRIEND LINK:

CONTACT US

No. 389 Chuanhong Road, Pudong New Area, Shanghai 201202, China

Tel: +86 17821945087

Online Service: 7*24h

© 2018 HUALONG All rights reserved. SiteMap