-

Electromechanical Universal Testing Machine

- Hydraulic Universal Testing Machine

- Automated Testing Systems

-

Horizontal Tensile Testing Machine

-

Elastomeric Bearing Testing Machine

-

Compression Testing Machine

-

High Temperature Creep Testing Machine

- Impact Testing Systems

-

Dynamic Testing Systems

-

Torsion Testing Machine

-

Bending Testing Machine

- Special Testing Machine

- Non-Metal Testing Machine

- Hardness Tester

- Metallographic Preparation Equipment

-

Microscope

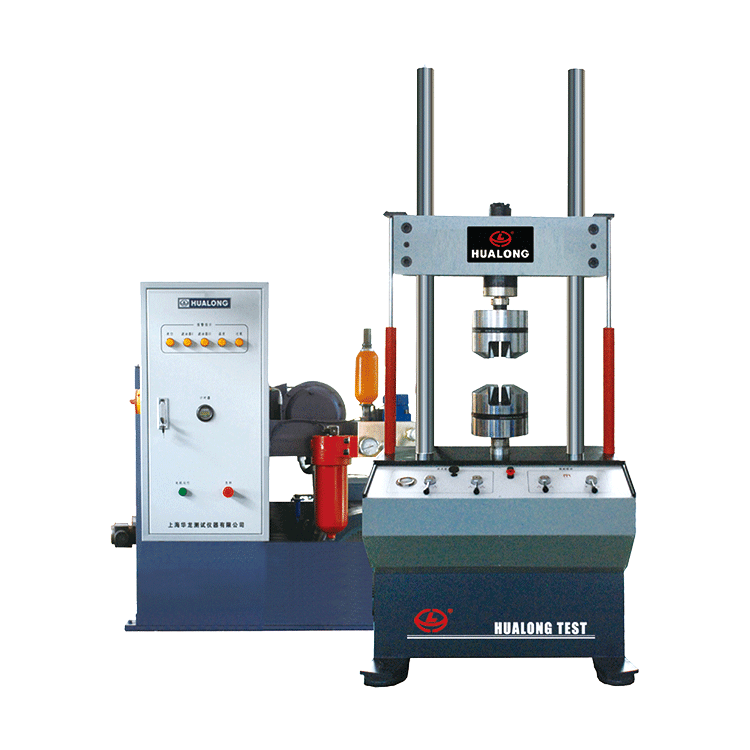

Electro-hydraulic pressure comprssion testing machine

The YA series electro-hydraulic pressure Testing Machine is mainly used for the mechanical properties test of concrete, building components and other materials.

This machine adopts the Structure of the main unit and the hydraulic system, which is compact and compact. It adopts hydraulic loading, electronic force measurement, automatic tracking and measurement with force and load rate, peak hold, automatic load calibration and other functions. The test data is automatically processed and displayed, and a random test report with test date, number, damage load, compressive strength, etc. is printed. This machine is suitable for the testing and analysis of mechanical properties of raw materials, incoming materials and finished Products in colleges and universities, factories and mines, quality supervision departments, and metrological verification.

This machine fully complies with the requirements of GB/T 2611-92 and GB/T 3722-92.

• Host structure

• Host

The main machine adopts the integral frame structure, which is equipped with working cylinders, pistons, upper and lower pressure plates and the like.

The load cylinder is a key component. In order to ensure its sensitivity, low friction and pressure stability, the design adopts international advanced composite sealing technology, which is made of high-quality materials and special techniques for precision manufacturing. It is equipped with safety limit, piston position indicator and so on. .

The test space is a manual screw adjustment, and a clearance eliminating mechanism is provided between the lead screw and the nut to eliminate the amount of movement between them.

The upper pressure plate is equipped with a ball-head sub-structure for automatic self-aligning.

Hydraulic source

The hydraulic system is the power source of the whole machine and is installed on the right side of the main unit. The axial piston high pressure pump is selected and connected to the motor through the elastic coupling and placed inside the fuel tank. The oil delivery valve is a valve block that integrates throttling and overflow. When the valve is closed, the oil output from the pump overflows completely back to the tank through the valve. The test and return valve can be adjusted according to actual needs to control flow and pressure.

All parts and assembly production procedures of the factory are strictly in accordance with ISO9001 quality assurance system for quality control.

• Performance characteristics

• With automatic load tracking measurement function

• Maximum load peak hold function

• With load rate dynamic display function

• With automatic load range switching

• Has a fast piston drop function

• Digital calibration function with accurate load realization, with binning overload protection, full load protection and position protection

Printed a random test report with test date, number, damage load, compressive strength, etc.

This machine adopts the Structure of the main unit and the hydraulic system, which is compact and compact. It adopts hydraulic loading, electronic force measurement, automatic tracking and measurement with force and load rate, peak hold, automatic load calibration and other functions. The test data is automatically processed and displayed, and a random test report with test date, number, damage load, compressive strength, etc. is printed. This machine is suitable for the testing and analysis of mechanical properties of raw materials, incoming materials and finished Products in colleges and universities, factories and mines, quality supervision departments, and metrological verification.

This machine fully complies with the requirements of GB/T 2611-92 and GB/T 3722-92.

• Host structure

• Host

The main machine adopts the integral frame structure, which is equipped with working cylinders, pistons, upper and lower pressure plates and the like.

The load cylinder is a key component. In order to ensure its sensitivity, low friction and pressure stability, the design adopts international advanced composite sealing technology, which is made of high-quality materials and special techniques for precision manufacturing. It is equipped with safety limit, piston position indicator and so on. .

The test space is a manual screw adjustment, and a clearance eliminating mechanism is provided between the lead screw and the nut to eliminate the amount of movement between them.

The upper pressure plate is equipped with a ball-head sub-structure for automatic self-aligning.

Hydraulic source

The hydraulic system is the power source of the whole machine and is installed on the right side of the main unit. The axial piston high pressure pump is selected and connected to the motor through the elastic coupling and placed inside the fuel tank. The oil delivery valve is a valve block that integrates throttling and overflow. When the valve is closed, the oil output from the pump overflows completely back to the tank through the valve. The test and return valve can be adjusted according to actual needs to control flow and pressure.

All parts and assembly production procedures of the factory are strictly in accordance with ISO9001 quality assurance system for quality control.

• Performance characteristics

• With automatic load tracking measurement function

• Maximum load peak hold function

• With load rate dynamic display function

• With automatic load range switching

• Has a fast piston drop function

• Digital calibration function with accurate load realization, with binning overload protection, full load protection and position protection

Printed a random test report with test date, number, damage load, compressive strength, etc.

Need help or have a question?

For more information on how Hualong can help your company profit through testing, please Click the button.FRIEND LINK:

CONTACT US

No. 389 Chuanhong Road, Pudong New Area, Shanghai 201202, China

Tel: +86 17821945087

Online Service: 7*24h

© 2018 HUALONG All rights reserved. SiteMap