-

Electromechanical Universal Testing Machine

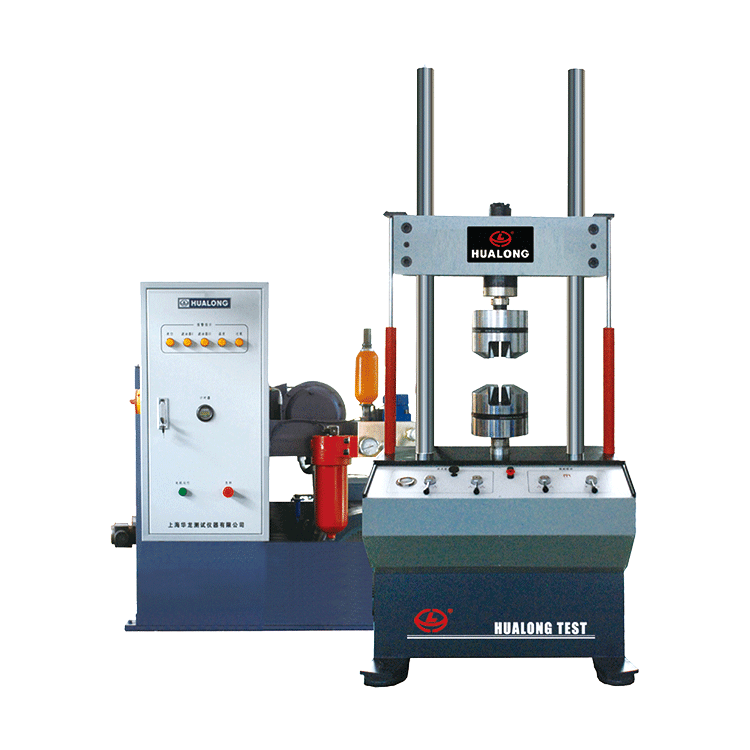

- Hydraulic Universal Testing Machine

- Automated Testing Systems

-

Horizontal Tensile Testing Machine

-

Elastomeric Bearing Testing Machine

-

Compression Testing Machine

-

High Temperature Creep Testing Machine

- Impact Testing Systems

-

Dynamic Testing Systems

-

Torsion Testing Machine

-

Bending Testing Machine

- Special Testing Machine

- Non-Metal Testing Machine

- Hardness Tester

- Metallographic Preparation Equipment

-

Microscope

Single column pressure testing equipment

Performance characteristics:

Software system: Chinese software package under Windows 7 platform.

Range mode: full scale is not divided, equivalent to seven.

High resolution: The resolution is ±500000 yards.

Automatic storage: test conditions, test results, and gauge position are automatically stored.

Automatic return: The crosshead automatically returns to the initial position of the test.

Automatic calibration: Load and elongation can be automatically calibrated according to the added standard value.

Multi-variable control: with control methods such as displacement, load, stress, elongation and strain.

Fine-tuning function: The crosshead can be finely adjusted for calibration verification.

Manual device: Multi-directional operating unit makes the adjustment of the cross head position more convenient.

Continuous test: After a batch of test parameters are set, continuous test can be performed.

Wide measuring range: Multiple sensors can be calibrated at the same time to extend the test range.

Data editing: After the test is completed, the data can be edited with the mouse on the test curve.

A variety of curves: a variety of curves such as stress-strain, force-elongation, force-time, intensity-time can be selected, and three different curves can be displayed on the same graph.

Curve comparison: The curves of the same group of samples can be superimposed and compared.

Graphical analysis: Any point on the test curve can be analyzed locally.

Report editing: Different report formats can be output according to user requirements.

A variety of uses: metal, non-metal and components can be stretched, compressed, bent, sheared, peeled, torn, low cycle, cycle, creep and other tests.

Double operation: computer, CTS-600 screen display table dual operating system unified combination, computer and CTS-600 can be tested and controlled separately.

Module control: Industrial control bus type electrical hardware, a variety of test Accessories are flexibly interchangeable, easy to function expansion, overhaul.

Efficient test: small load, large extension material stretching, crosshead can automatically return at 1000mm/min speed; large load, high strength material stretching, can be tested by quick and reliable clamping with hydraulic clamps.

Multiple protection: The servo system has protections such as overcurrent, overvoltage, overspeed, undercurrent and undervoltage; the crosshead stroke has three limits of program control limit, limit limit and software limit; load sensor and electronic Extensometer have overrange Protection; emergency braking can be performed in an emergency.

Automatic identification: After the sample is destroyed, it is automatically identified and the next function is completed as intended.

Automatic diagnosis: When the servo system fails, the cause of the fault can be automatically diagnosed and the code of the fault is automatically stored in the servo drive to quickly find and eliminate the fault.

Dynamic display: During the test, the load, elongation, displacement and selected test curve are dynamically displayed on the main control screen in real time as the test progresses.

Peak hold: During the entire test, the maximum value of the test item is always displayed on the screen window following the test.

Convenient zero adjustment: load, elongation, and displacement can be manually zeroed by pressing one button, and the system automatically performs zero adjustment at the beginning of the test.

Multi-purpose machine: It can be equipped with different specifications of sensors, Extensometers and fixtures to widen the measurement range, thus achieving multi-purpose use.

The first domestic push: the unique true stress-strain test processing function in China can reflect the damage process of the sample under tensile force at a glance.

Automatic variable scale: If the curve coordinates such as load and elongation are not selected properly, the coordinates can be automatically changed according to the measured value to ensure that the curve is displayed on the screen in the largest form in any case.

Extended analysis: Any segment on the test curve can be partially magnified and printed.

Implementation standards: meet ISO, JIS, ASTM, DIN, GB and other test method standards.

Software system: Chinese software package under Windows 7 platform.

Range mode: full scale is not divided, equivalent to seven.

High resolution: The resolution is ±500000 yards.

Automatic storage: test conditions, test results, and gauge position are automatically stored.

Automatic return: The crosshead automatically returns to the initial position of the test.

Automatic calibration: Load and elongation can be automatically calibrated according to the added standard value.

Multi-variable control: with control methods such as displacement, load, stress, elongation and strain.

Fine-tuning function: The crosshead can be finely adjusted for calibration verification.

Manual device: Multi-directional operating unit makes the adjustment of the cross head position more convenient.

Continuous test: After a batch of test parameters are set, continuous test can be performed.

Wide measuring range: Multiple sensors can be calibrated at the same time to extend the test range.

Data editing: After the test is completed, the data can be edited with the mouse on the test curve.

A variety of curves: a variety of curves such as stress-strain, force-elongation, force-time, intensity-time can be selected, and three different curves can be displayed on the same graph.

Curve comparison: The curves of the same group of samples can be superimposed and compared.

Graphical analysis: Any point on the test curve can be analyzed locally.

Report editing: Different report formats can be output according to user requirements.

A variety of uses: metal, non-metal and components can be stretched, compressed, bent, sheared, peeled, torn, low cycle, cycle, creep and other tests.

Double operation: computer, CTS-600 screen display table dual operating system unified combination, computer and CTS-600 can be tested and controlled separately.

Module control: Industrial control bus type electrical hardware, a variety of test Accessories are flexibly interchangeable, easy to function expansion, overhaul.

Efficient test: small load, large extension material stretching, crosshead can automatically return at 1000mm/min speed; large load, high strength material stretching, can be tested by quick and reliable clamping with hydraulic clamps.

Multiple protection: The servo system has protections such as overcurrent, overvoltage, overspeed, undercurrent and undervoltage; the crosshead stroke has three limits of program control limit, limit limit and software limit; load sensor and electronic Extensometer have overrange Protection; emergency braking can be performed in an emergency.

Automatic identification: After the sample is destroyed, it is automatically identified and the next function is completed as intended.

Automatic diagnosis: When the servo system fails, the cause of the fault can be automatically diagnosed and the code of the fault is automatically stored in the servo drive to quickly find and eliminate the fault.

Dynamic display: During the test, the load, elongation, displacement and selected test curve are dynamically displayed on the main control screen in real time as the test progresses.

Peak hold: During the entire test, the maximum value of the test item is always displayed on the screen window following the test.

Convenient zero adjustment: load, elongation, and displacement can be manually zeroed by pressing one button, and the system automatically performs zero adjustment at the beginning of the test.

Multi-purpose machine: It can be equipped with different specifications of sensors, Extensometers and fixtures to widen the measurement range, thus achieving multi-purpose use.

The first domestic push: the unique true stress-strain test processing function in China can reflect the damage process of the sample under tensile force at a glance.

Automatic variable scale: If the curve coordinates such as load and elongation are not selected properly, the coordinates can be automatically changed according to the measured value to ensure that the curve is displayed on the screen in the largest form in any case.

Extended analysis: Any segment on the test curve can be partially magnified and printed.

Implementation standards: meet ISO, JIS, ASTM, DIN, GB and other test method standards.

Need help or have a question?

For more information on how Hualong can help your company profit through testing, please Click the button.FRIEND LINK:

CONTACT US

No. 389 Chuanhong Road, Pudong New Area, Shanghai 201202, China

Tel: +86 17821945087

Online Service: 7*24h

© 2018 HUALONG All rights reserved. SiteMap